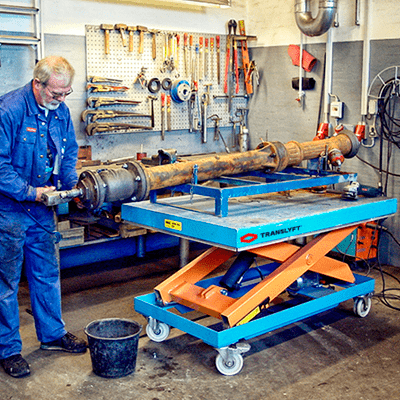

Solutions

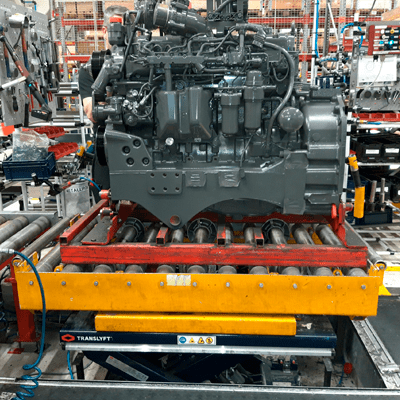

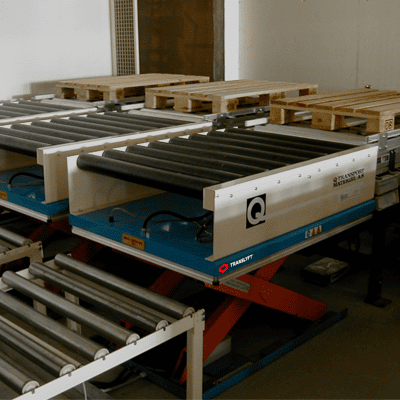

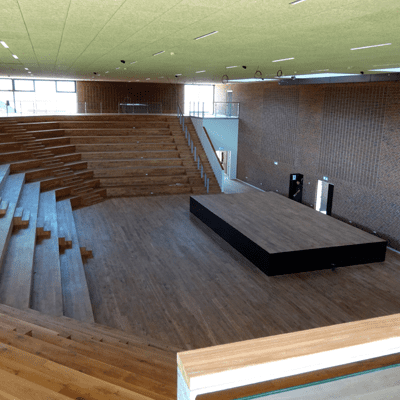

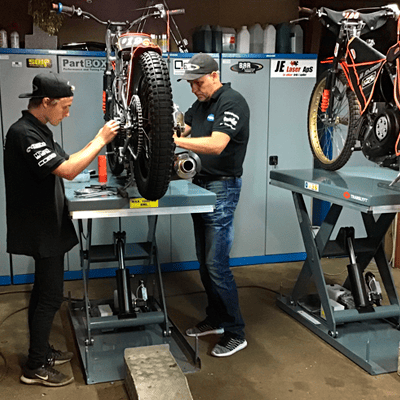

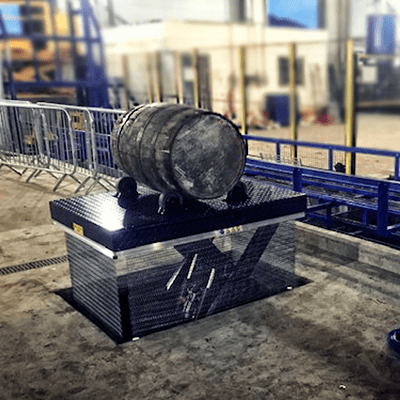

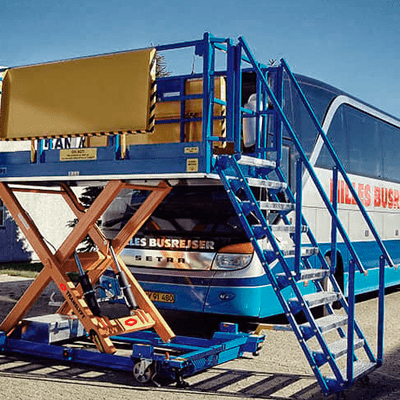

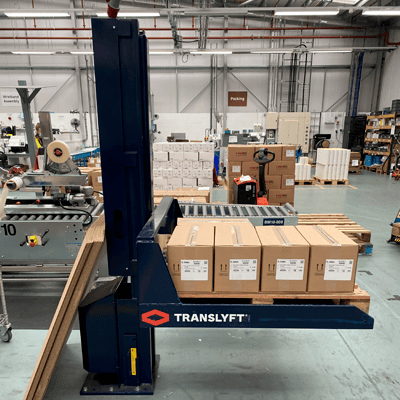

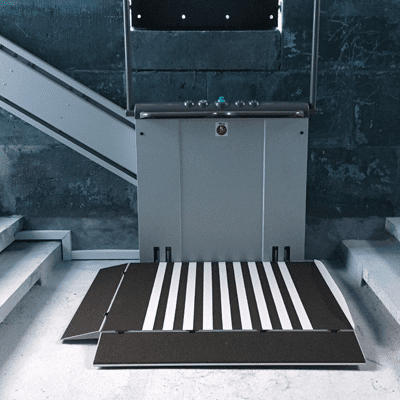

At Translyft, we need to fully understand your work process to find the right solution for your exact requirements. We know that each lift is unique and that each company has it's own specific work processes and each station it's individual functionalities. In 9 out of 10 cases this means that we end up with a bespoke solution either tweaking one of our existing models or a completely new specification.

TRANSLYFT's contribution to a company's lifting solutions is not only a better work environment, improved reliability and efficiency. Both our advice and our holistic solutions contribute positively to the competitiveness and future security of the work process.